|

|

|

The High school of Applied Arts for

glassmaking in Železný Brod Hot shape glass

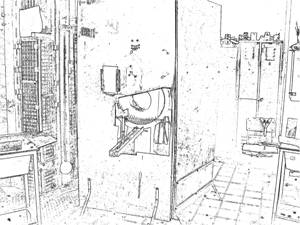

department Ours school glass-works does‘n consist from only surnace, but there are much more other places which can not produce glass products without.

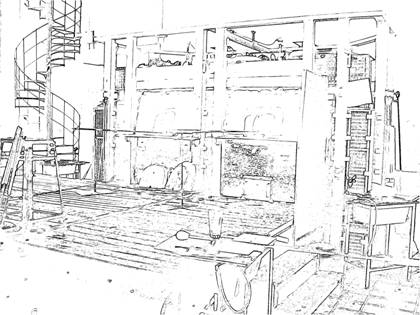

Firsly I introduce you with all glass-works precinct ( we are looking at a place where ordinary visitors never come),I am going to describe you single equipment and tools and further single technology, which is students are tought during four year class. In the end with talk something about seclusion works. Before we can produce something glass. First we must melt glass mass. Advanced procass takes place upstairs below surface where is batch mixing plant.

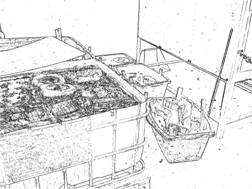

In batch mixing plant we don’t mix the glass-batch from raw materials as soda, silica sand, limestone and metals oxide,but uses already mixed glass-batch, which is delivered by various some firms. The glass-batch is poured into the surnase and dice are added usually obout 30-40%. We have only two kinds of molten glass name Czech Crystal and cobalt.

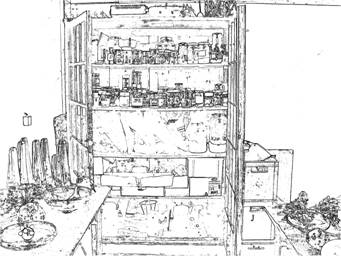

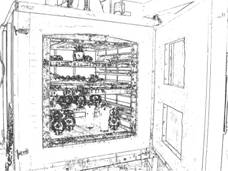

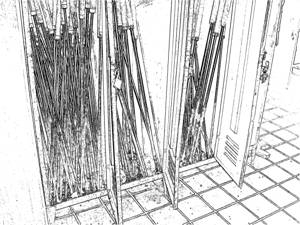

Upstairs below glass-works the ruby store is situted. It is a small room where there are coloured glass rods and coloured dust, which are used for different production technology to glass-staining during industrial process are put on shelfs.

Uusing the ruby and dust we have achieved the ritch colour spectrum.About 70 shade various colours.

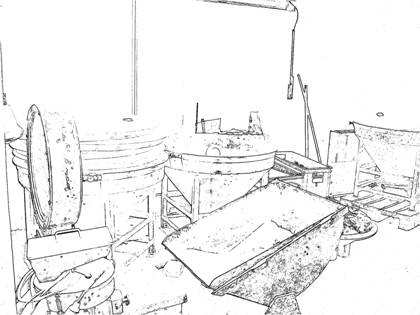

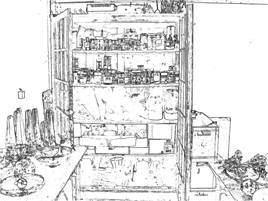

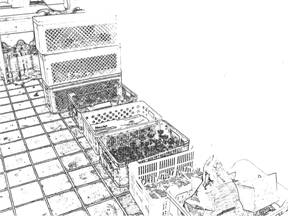

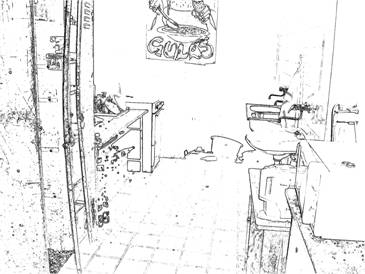

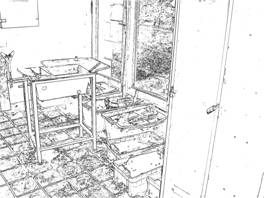

The other rooms upstairs below glass-works are driving case with electric breaker,room with compressor,warehousing precinct with reserve pans and tubs with water where there are glass forms.If glass forms were on the air,they would craze.

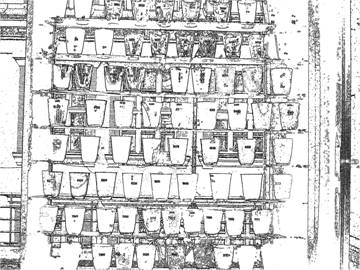

Very important room is also „pukarna“where the right cooled finished goods is in single box as where there are composition drink glasses, gobblets, saucers,dishes, sundrys various vases and other hotglass products are storaed up..

There is also deposit of colours and coloured dust,which we normaly use.

and warms them by flame.The glasse breaks blows out in the accurate locate place.

All glass-works is operated by a computer from a small room.

Naturally there is also a kitchen where we can make breakfast and a cloak-room. That’s all about glass-works rooms.

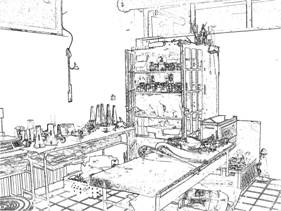

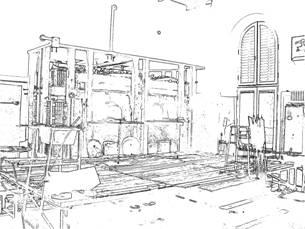

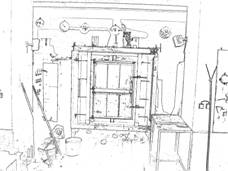

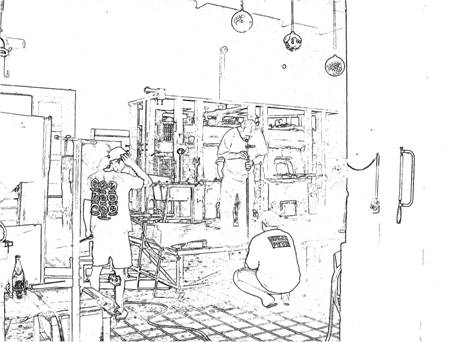

Hardware smelting works Of curse the most important of all is the surnace with two pans and two glory-holes. His heated by electrical warm operated by a computer.

Very important are glory holes.The glory hole heats the

glass products during the process.

Anotherindispensable place of equipment is an anneling kiln where finished goods is slowly cooled down from 500°C to common temperatures of obout 30°C if glass wasn't cooled Properly it would cracke.We also use a malleableizing

furnace for warming the pan up before incorporating into the surnace within

exchanging the pan.

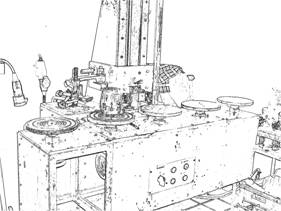

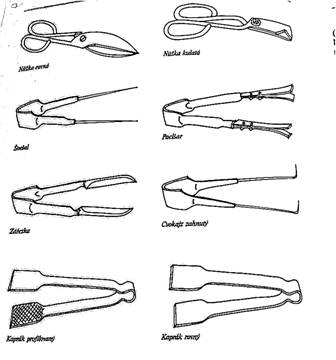

The tools which we used. The main tools which we use are: bradawl, peg, shears, hendle shears, cats eye shears, pincers, pincers, pinching tool, knob tools, mouth tools, woodjack, cracking off iron.

The others are „šajtpálka“, shaping block of spoon form and

pin wooden tools which we must soak very

often but not too much because of their fast wcaring out.

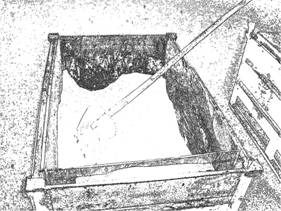

Sheet-metal tank on four legs serves as working post.There is some to cool down water blowing pipes and put off tools.

Therev are blowing pipes and sticks perhaps most important tools for hand-made glass forming.

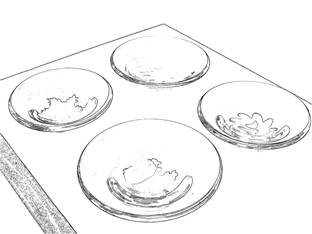

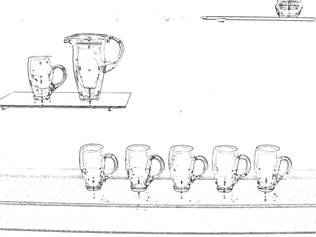

Technologies During four years students learn obout basis glasswork trade.The main technology,which we have learned is blowing drinking glass into wooden forms, for example various drinking glasses and tankards for beer with handles, frigger vasses, deserts planes decorated different colours.Other art products are decorative subjects as peper-wieghts, ash-pan trays, different glasses animals etc.

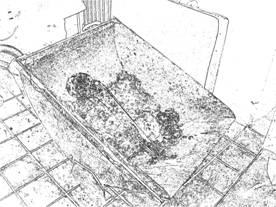

I can‘t forget about saffety at work glass-works. Because the glass-works is warm operation we must still take care of not to bem burned, a supervise master, shows new glasswork techniqeus.Students must drink a lot in order not to be dehydrated, because there is very hot and every body sweats a lot. Finaly there is seclusion works. Seclusion works are done by students every year. So they rate their work.Seclusion works consists of two parts: graphic part and practical parting.Graphic part every student first designs engaged subjeting studio.Practical part students preparate their own design then make it in glass-works. In classe one had seclusion works only as graphic,in classe two designed tankards set for beer with tankard and in classe three we have done set dishes connection identical decorating. You can see the exhibit of my seclusion works in the pictures.

There are several pictures from our studio I hope,that you heve obtained the new information. Glasswoks trade is splendid craft and work and like it certainly everybody.

Creative Artist 3D grafika a 3D animace autor: jiřík, Jiří Jansa. Kontakt. Poslední aktualizace 2.června.2006.

|